The THT or Through Hole Technology has been in a great use for more than a century and has also been proven to be very reliable, can secure huge parts and maintain connectivity in high temperatures and high power. On the other hand, SMT or Surface Mount Technology is meant to accommodate smaller and lighter parts. SMT is also useful for complex trace routing as compared to THT and is more cost effective. No matter what kind of assembly method is used, there are standards to be followed for solder joint quality that must be fulfilled like J-STD-001, J-STD-002, and J-STD-003. The basic steps for the assembly process are the same for THT or SMT.

Here are the steps for PCBA or printed circuit board assembly:

- Preparing the bare board derived from the fabrication process.

- Component placement.

- Component soldering.

- Inspection and correction.

- Cleaning the board.

Through Hole Technology or THT process steps

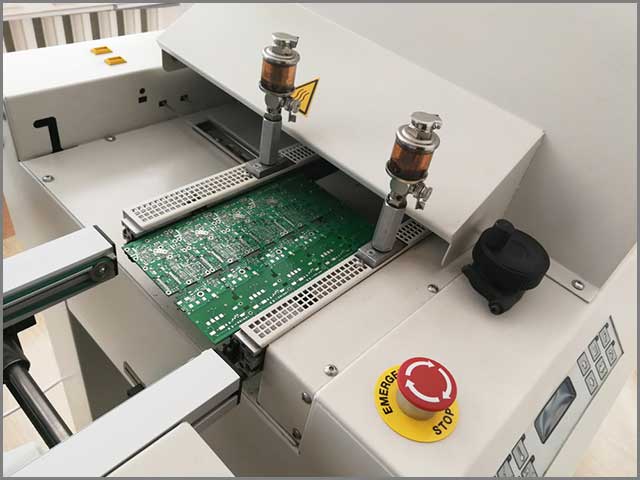

- Component placement For THT

Here the component leads or pins are injected via the board

- Inspection and correction

In case of any deviation or errors, the placement will be rectified and monitored

- Wave soldering

When it comes to wave soldering, one side of the complete board is subjected to a wave of solder. As the board tends to traverse the wave, the components of through hole are also simultaneously soldered.

Surface Mount Technology or SMT process steps

- Applying the solder paste

When it comes to SMT, the first layer of solder paste is applied to keep the components in place for soldering.

- Component mounting

The components are kept on footprints that have conductor pads that will be well soldered to give away the electrical connections.

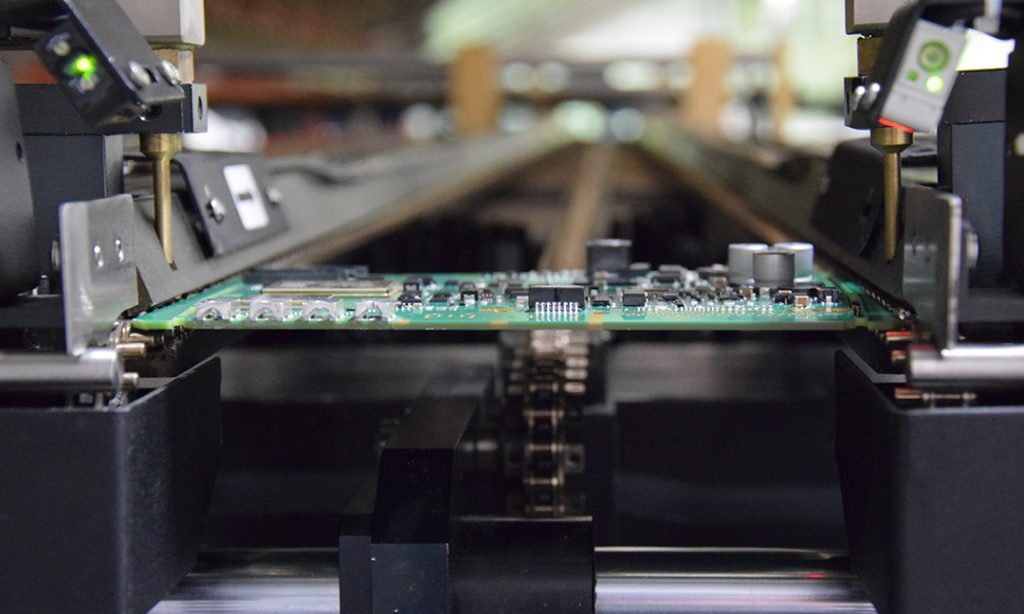

- Reflow soldering

The reflow soldering is done in an oven that has a temperature that goes beyond 235°C.

Differences between THT or SMT

THT or Through Hole Technology has a stronger component bond, ideal for bigger components and especially if they are put into mechanic stress. It is also great for higher power tolerance and high temperature parts.

SMT or Surface Mount Technology is a faster process and is more cost effective than THT. It is ideal for smaller and denser boards, works better on complicated routing and double-sided component mounting as well.

For more, visit the website.

Comments are closed.